3D-печать

Компания «АП-Проект» имеет богатый опыт в области изготовления прототипов на заказ, печати любых изделий и деталей на 3D-принтере с использованием различных технологий. Прототипирование является одним из главных направлений деятельности компании, технологические возможности позволяют изготавливать прототипы габаритами до 800 мм. Приоритетами в работе компании «АП-Проект» являются качество и удовлетворение потребностей наших Клиентов.

3D-печать по технологии FDM

Технология FDM в 3D-печати термопластиками основана на послойном нанесении расплавленной полимерной нити. Благодаря доступности оборудования и материалов это одна из самых распространенных и дешевых технологий трехмерной печати.

При необходимости изготовления функционального прототипа с минимальной стоимостью и сроками, можем предложить Вам FDM технологию (послойное наложение расплавленной полимерной нити).

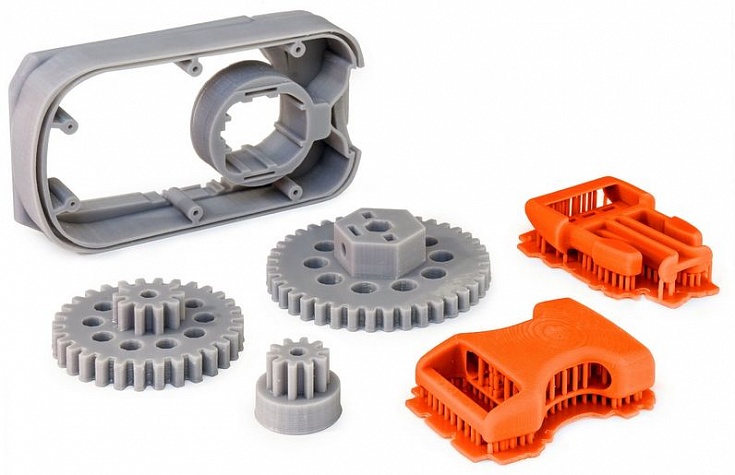

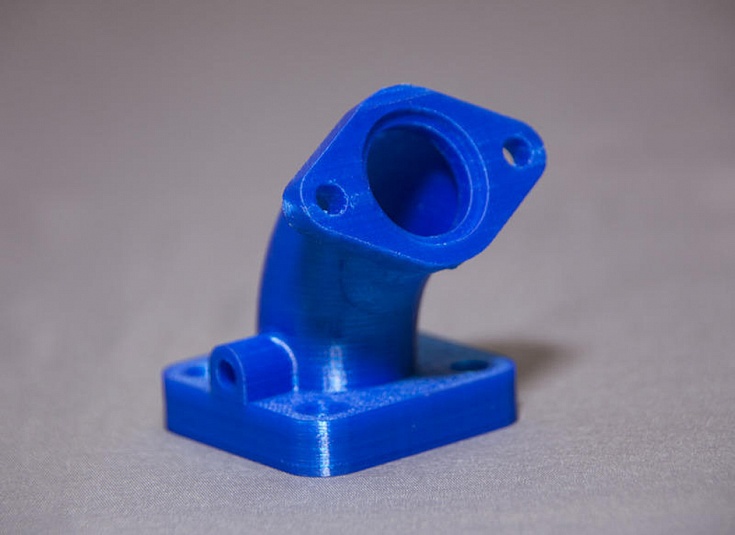

FDM технология позволяет с легкостью напечатать функциональные прототипы.

Преимущества:

- низкая стоимость печати прототипов;

- функциональность;

- прочные износостойкие изделия.

Примеры выполненных работ по технологии FDM:

3D-печать по технологии SLA

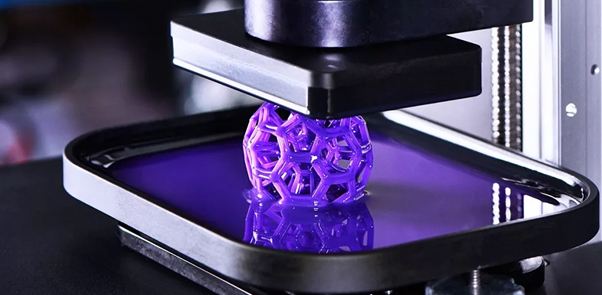

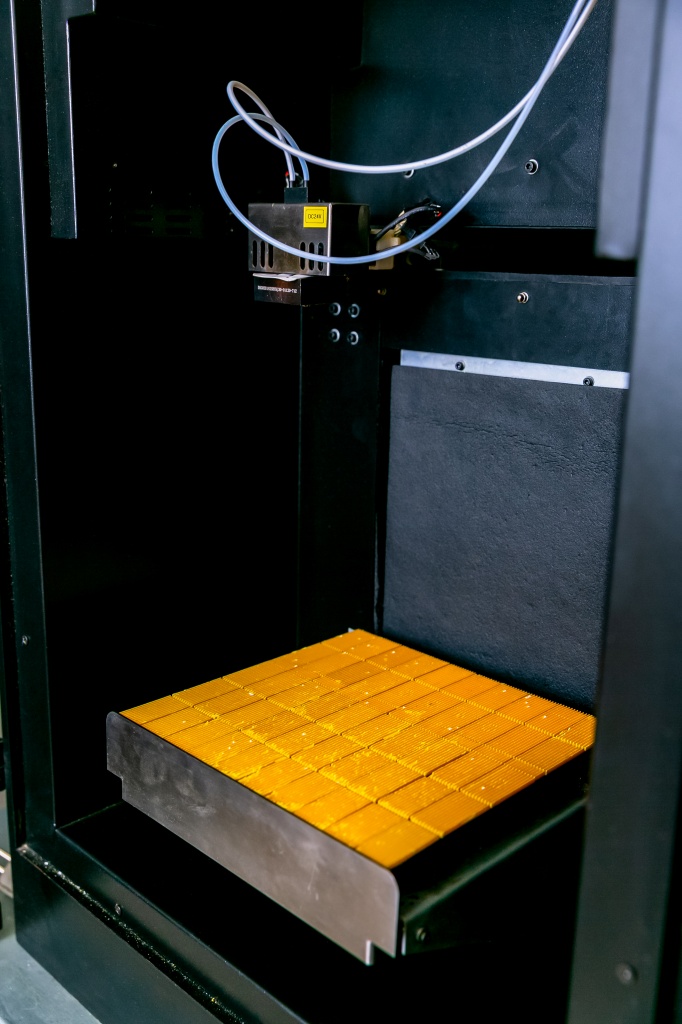

Для изготовления прототипа с высокой точностью предлагаем Вам рассмотреть услуги 3D-печати в Нижнем Новгороде по технологии лазерной стереолитографии (SLA-технология) из фотополимера SOMOS GP plus.

SLA-технология позволяет Вам получить прототипы любой сложности и структуры в том числе тонкостенные и мелкие детали. В дальнейшим напечатанный прототип можно использовать в качестве мастер-модели при вакуумном литье в силиконовые формы.

Преимущества данной технологии:

- отличная детализация и гладкость поверхности позволяет использовать выращенный прототип в качестве готового изделия;

- легкая обработка изготовленного прототипа.

Примеры выполненных работ по технологии SLA:

Финишная доводка прототипов

По желанию клиента прототип проходит этап финишной доводки, который выполнен ручным методом при помощи полировки и покраски. В результате финишной обработки устраняются следы послойного строения, поверхности придается необходимая гладкость или текстура. Вы можете выбрать желаемый вид поверхности – глянцевую, мелкий песок, матовую, либо текстурированную по каталогу Mold-Tech.

Примеры выполненных работ по доводке прототипов:

Для печати прототипов на заказ в компании «АП-Проект» требуется 3Д модель в формате STL или STEP. При получении модели наши технические специалисты проверят файлы на примечания и наличие ошибок.

|

Оформите запрос на недорогую 3Д печать в Нижнем Новгороде, и наш менеджер свяжется с Вами в ближайшее время для уточнения деталей заказа и предоставления актуальной информации о ценах, скидках, способах оплаты и доставки.

|

Заказать услугу

|