Проектирование и изготовление деталей из пластика

Проектирование и изготовление деталей из пластика

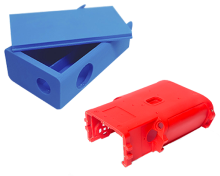

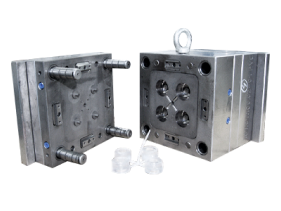

Наши технологии изготовления корпусов для приборов

Услуги по проектированию и изготовлению деталей из пластика

С 2009 года технические эксперты компании «АП-Проект» помогают решать производственные задачи частным заказчикам и компаниям, специализирующимся на выпуске продукции в сфере автомобиле- и приборостроения, медицины, электроники, архитектуры, дизайна и рекламы.

«АП-Проект» сегодня

Современные технологии, расширенные производственные возможности, гибкая ценовая политика и персональный подход к реализации каждого проекта — сотрудничать с нами выгодно и удобно.

«АП-Проект» имеет большую сеть региональных представительств и оперативно реагирует на потребности партнёров по всей России, стремящихся изготовить качественные изделия, приобрести специальное оборудование или получить квалифицированные услуги в области инжиниринга.

Консультационные центры расположены в Нижнем Новгороде, Москве, Санкт-Петербурге, Новосибирске, Екатеринбурге, Самаре, Казани.

Мы гарантируем

Отзывы клиентов

Как начать сотрудничество?

Наши партнеры

Сб-Вс: выходной